Strong Powerful Permanent Neodymium

| Price: | 0.01~5.0 USD |

| Payment Terms: | T/T,L/C,WU;PayPal |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

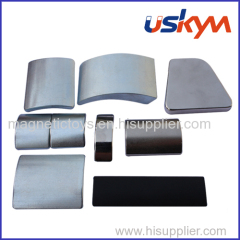

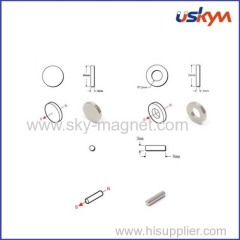

1 Vast range of complex shapes and sizes

2 Economical cost

3 Ideal for high temperature application up to 550 °C

Specifications:

Neodymium magnet

1.high quality,

2.customized size,

3.competitive price

4.fast and safe delivery,excellent services

| Magnetic properties of Sintered Neodymium Magnet (NdFeB magnet): | |||||

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. Operating Temperature |

| Br mT (kGs) | Hcb kA/m (kOe) | Hcj kA/m (kOe) | ( BH )max kJ/m 3 (MGOe) | Tw | |

| N35 | 1170-1220 (11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 955 ( ≥ 12) | 263-287 (33-36) | 80 deg |

| N38 | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 955 ( ≥ 12) | 287-310 (36-39) | 80 deg |

| N40 | 1250-1280 (12.5-12.8) | ≥ 907 ( ≥ 11.4) | ≥ 955 ( ≥ 12) | 302-326 (38-41) | 80 deg |

| N42 | 1280-1320 (12.8-13.2) | ≥ 915 ( ≥ 11.5) | ≥ 955 ( ≥ 12) | 318-342 (40-43) | 80 deg |

| N45 | 1320-1380 (13.2-13.8) | ≥ 923 ( ≥ 11.6) | ≥ 955 ( ≥ 12) | 342-366 (43-46) | 80 deg |

| N48 | 1380-1420 (13.8-14.2) | ≥ 923 ( ≥ 11.6) | ≥ 876 ( ≥ 12) | 366-390 (46-49) | 80 deg |

| N50 | 1400-1450 (14.0-14.5) | ≥ 796 ( ≥ 10.0) | ≥ 876 ( ≥ 11) | 382-406 (48-51) | 60 deg |

| N52 | 1430-1480 (14.3-14.8) | ≥ 796 ( ≥ 10.0) | ≥ 876 ( ≥ 11) | 398-422 (50-53) | 60 deg |

| 30M | 1080-1130 (10.8-11.3) | ≥ 796 ( ≥ 10.0) | ≥ 1114 ( ≥ 14) | 223-247 (28-31) | 100 deg |

| 33M | 1130-1170 (11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 1114 ( ≥ 14) | 247-263 (31-33) | 100 deg |

| 35M | 1170-1220 (11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 1114 ( ≥ 14) | 263-287 (33-36) | 100 deg |

| 38M | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 1114 ( ≥ 14) | 287-310 (36-39) | 100 deg |

| 40M | 1250-1280 (12.5-12.8) | ≥ 923 ( ≥ 11.6) | ≥ 1114 ( ≥ 14) | 302-326 (38-41) | 100 deg |

| 42M | 1280-1320 (12.8-13.2) | ≥ 955 ( ≥ 12.0) | ≥ 1114 ( ≥ 14) | 318-342 (40-43) | 100 deg |

| 45M | 1320-1380 (13.2-13.8) | ≥ 995 ( ≥ 12.5) | ≥ 1114 ( ≥ 14) | 342-366 (43-46) | 100 deg |

| 48M | 1360-1430 (13.6-14.3) | ≥ 1027 ( ≥ 12.9) | ≥ 1114 ( ≥ 14) | 366-390 (46-49) | 100 deg |

| 50M | 1400-1450 (14.0-14.5) | ≥ 1033 ( ≥ 13.0) | ≥ 1114 ( ≥ 14) | 382-406 (48-51) | 100 deg |

| 30H | 1080-1130 (10.8-11.3) | ≥ 796 ( ≥ 10.0) | ≥ 1353 ( ≥ 17) | 223-247 (28-31) | 120 deg |

| 33H | 1130-1170 (11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 1353 ( ≥ 17) | 247-271 (31-34) | 120 deg |

| 35H | 1170-1220 (11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 1353 ( ≥ 17) | 263-287 (33-36) | 120 deg |

| 38H | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 1353 ( ≥ 17) | 287-310 (36-39) | 120 deg |

| 40H | 1250-1280 (12.5-12.8) | ≥ 923 ( ≥ 11.6) | ≥ 1353 ( ≥ 17) | 302-326 (38-41) | 120 deg |

| 42H | 1280-1320 (12.8-13.2) | ≥ 955 ( ≥ 12.0) | ≥ 1353 ( ≥ 17) | 318-342 (40-43) | 120 deg |

| 45H | 1300-1360 (13-13.6) | ≥ 963 ( ≥ 12.1) | ≥ 1353 ( ≥ 17) | 326-358 (43-46) | 120 deg |

| 48H | 1370-1430 (13.7-14.3) | ≥ 995 ( ≥ 12.5) | ≥ 1353 ( ≥ 17) | 366-390 (46-49) | 120 deg |

| 30SH | 1080-1130 (10.8-11.3) | ≥ 804 ( ≥ 10.1) | ≥ 1592 ( ≥ 20) | 223-247 (28-31) | 150 deg |

| 33SH | 1130-1170 (11.3-11.7) | ≥ 844 ( ≥ 10.6) | ≥ 1592 ( ≥ 20) | 247-271 (31-34) | 150 deg |

| 35SH | 1170-1220 (11.7-12.2) | ≥ 876 ( ≥ 11.0) | ≥ 1592 ( ≥ 20) | 263-287 (33-36) | 150 deg |

| 38SH | 1220-1250 (12.2-12.5) | ≥ 907 ( ≥ 11.4) | ≥ 1592 ( ≥ 20) | 287-310 (36-39) | 150 deg |

| 40SH | 1240-1280 (12.5-12.8) | ≥ 939 ( ≥ 11.8) | ≥ 1592 ( ≥ 20) | 302-326 (38-41) | 150 deg |

| 42SH | 1280-1320 (12.8-13.2) | ≥ 987 ( ≥ 12.4) | ≥ 1592 ( ≥ 20) | 318-342 (40-43) | 150 deg |

| 45SH | 1320-1380 (13.2-13.8) | ≥ 1003 ( ≥ 12.6) | ≥ 1592 ( ≥ 20) | 342-366 (43-46) | 150 deg |

| 28UH | 1020-1080 (10.2-10.8) | ≥ 764 ( ≥ 9.6) | ≥ 1990 ( ≥ 25) | 207-231 (26-29) | 180 deg |

| 30UH | 1080-1130 (10.8-11.3) | ≥ 812 ( ≥ 10.2) | ≥ 1990 ( ≥ 25) | 223-247 (28-31) | 180 deg |

| 33UH | 1130-1170 (11.3-11.7) | ≥ 852 ( ≥ 10.7) | ≥ 1990 ( ≥ 25) | 247-271 (31-34) | 180 deg |

| 35UH | 1180-1220 (11.8-12.2) | ≥ 860 ( ≥ 10.8) | ≥ 1990 ( ≥ 25) | 263-287 (33-36) | 180 deg |

| 38UH | 1220-1250 (12.2-12.5) | ≥ 876 ( ≥ 11.0) | ≥ 1990 ( ≥ 25) | 287-310 (36-39) | 180 deg |

| 40UH | 1240-1280 (12.5-12.8) | ≥ 899 ( ≥ 11.3) | ≥ 1990 ( ≥ 25) | 302-326 (38-41) | 180 deg |

| 28EH | 1040-1090 (10.4-10.9) | ≥ 780 ( ≥ 9.8) | ≥ 2388 ( ≥ 30) | 207-231 (26-29) | 200 deg |

| 30EH | 1080-1130 (10.8-11.3) | ≥ 812 ( ≥ 10.2) | ≥ 2388 ( ≥ 30) | 223-247 (28-31) | 200 deg |

| 33EH | 1130-1170 (11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 2388 ( ≥ 30) | 247-271 (31-34) | 200 deg |

| 35EH | 1170-1220 (11.7-12.2) | ≥ 876 ( ≥ 11.0) | ≥ 2388 ( ≥ 30) | 263-287 (33-36) | 200 deg |

| 38EH | 1220-1250 (12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 2388 ( ≥ 30) | 287-310 (36-39) | 200 deg |

| 30AH | 1080-1120 (10.8-11.2) | ≥ 812 ( ≥ 10.2) | ≥ 2785 ( ≥ 35) | 223-255 (28-32) | 220 deg |

| 33AH | 1120-1170 (11.2-11.7) | ≥ 812 ( ≥ 10.2) | ≥ 2785 ( ≥ 35) | 247-271 (31-34) | 220 deg |

| Physical and Mechanical Properties of Neodymium Magnet: | |||||

| Thermal Conductivity | 7.7 kcal/m-h-° C | ||||

| Young' s Modulus | 1.7 x 104 kg/mm2 | ||||

| Bending Strength | 24 kg/mm2 | ||||

| Compressive Strength | 80 kg/mm2 | ||||

| Electrical Resistivity | 160 µ -ohm-cm/cm2 | ||||

| Density | 7.4-7.55 g/cm3 | ||||

| Vickers Hardness | 500 - 600 | ||||

| Available coatings for sintered Neodymium Magnet (NdFeB magnet): | |||||

| Available Coatings: | |||||

| Surface | Coating | Thickness (Microns) | Color | Resistance | |

| Passivation | 1 | Silver Grey | Temporary Protection | ||

| Nickel | Ni+Ni | 10.0-20 | Bright Silver | Excellent against Humidity | |

| Ni+Cu+Ni | |||||

| Zinc | Zn | 8.0-20 | Bright Blue | Good Against Salt Spray | |

| C-Zn | Shinny Color | Excellent Against Salt Spray | |||

| Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity | |

| Gold | Ni+Cu+Au | 10.0-20 | Gold | Superior Against Humidity | |

| Copper | Ni+Cu | 10.0-20 | Gold | Temporary Protection | |

| Epoxy | Epoxy | 15-25 | Black, Red, Grey | Excellent Against Humidity & Salt Spray | |

| Ni+Cu+Epoxy | |||||

| Zn+Epoxy | |||||

| Chemical | Ni | 10.0-20 | Silver Grey | Excellent Against Humidity | |

| Parylene | Parylene | 5.0-20 | Grey | Excellent Against Humidity, Salt Spray. Superior Against Solvents, Gases, Fungi and Bacteria. FDA Approved. | |

Application:

Warnings:

Neodymium magnets attract each other with almost twice the force that they use to attract

steel objects.They also attract each other through very large distances, even small magnets

will attract each other through the thickness of your finger!

Contact us:

Please do no hesitate to contact with us if you have any questions or requests on magnet.

You can inquiry either by email/fax or instant message

We are pleased to offer your service and respond within 12 hours

Contact person:Julia Fung

Skype: julia126126

Tel:+86-574-88229324Ext811

Relevant Shipping Advantage:

1) Appointed forwarder is welcome

2) We can ship by express, air & sea

3) We have big discount on our won forwarder, and mainly world-wide express such as : DHL, UPS, Fedex

Welcome to contact with us!

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

You May Like:

Product (539)

- Sintered NdFeB magnets (327)

- Bonded NdFeB magnets (4)

- SmCo magnets (13)

- AlNiCo magnets (13)

- Ferrite magnets (40)

- Flexible magnets (47)

- Permanent lifting magnet (7)

- Magnetic Assemblies (30)

- Magnet Application (16)

- Neocube Magnets (10)

- Novel Magnetic Items (21)

- Magnetic Field Viewing Film (6)

- Magnetic Jewellery (3)

-

Pneumatic Tapping Machines

(2)

.jpg)

.jpg)

.jpg)