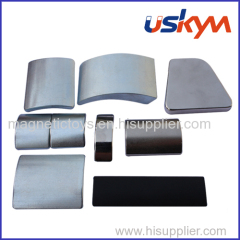

Rare Earth Neodymium/rare earth NdFeB magnets

| Price: | 0.01 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Neo magnets are known for their high temperature resistance, making them durable and functional in temperatures exceeding 200°C.

Rare earth Neodymium magnets (NdFeB) have been available for industrial use since 1984. Neo magnets have extremely high magnetic energy and therefore are used in applications which require high powered magnets, as well as applications where size and weight reduction are of interest or need to be considered. These qualities have made NdFeb magnets preferable over the commonly used larger and less powerful Ferrite magnets.

Neodymium magnets can be divided into three main groups:

Regular Neodymium

High corrosion resistant Neodymium

Bonded Neodymium (Isotropic): Manufactured by the injection of plastic material and Neodymium into a mold. This production method yields a very precise magnet which does not require further grinding and does not suffer substantial current loss.

Neo magnets are known for their high temperature resistance, making them durable and functional in temperatures exceeding 200°C. This quality makes them ideal for heavy industry applications. Sintered Neodymium, however, is sensitive to oxidization and can develop corrosion, so magnets are usually coated with Nickel for their protection.

Applications for Neo Magnets

NdFeb magnets can be used for a wide variety of applications:

Electronics – Sensors, hard disk drives, sophisticated switches, electro-mechanical devices etc.

Auto Industry – DC motors (hybrid and electric), small high-performance motors, power steering.

Medical – MRI equipment and scanners.

Clean Tech Energy – Water flow enhancement, wind turbines.

Magnetic Separators – Used for recycling, food and liquids QC, waste removal.

Magnetic Bearing – Used for highly sensitive and delicate procedures in various heavy industries.

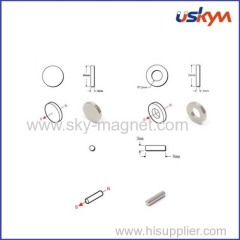

Properties of Neodymium Iron Boron magnets:

Neo magnets are graded by two major criteria: Magnetic value and resistance to temperature.

The use of Iron and Boron in the magnetic industry has made for a compact, highly efficient and cost-effective magnet, demonstrating high remanence and coercivity.

By changing the type of alloy, it is possible to control of the magnetic value and adapt the strength of the magnet to the required application.

Dysprosium and Terbium are added to the alloy to maintain and improve the magnet's properties. This enables use at high temperatures making these magnets able to withstand working temperatures of more than 200°C.

Sintered Neodymium magnet is highly prone to oxidation and corrosion, therefore the use of different coatings such as E-cote (a layer of epoxy), Nickel plating or Copper Nickel double plating is essential for protection. These improve the magnet's lifespan and ensure a high-quality product.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

You May Like:

Product (539)

- Sintered NdFeB magnets (327)

- Bonded NdFeB magnets (4)

- SmCo magnets (13)

- AlNiCo magnets (13)

- Ferrite magnets (40)

- Flexible magnets (47)

- Permanent lifting magnet (7)

- Magnetic Assemblies (30)

- Magnet Application (16)

- Neocube Magnets (10)

- Novel Magnetic Items (21)

- Magnetic Field Viewing Film (6)

- Magnetic Jewellery (3)

-

Pneumatic Tapping Machines

(2)

.jpg)

.jpg)

.jpg)