|

Sky Magnetech (Ningbo) Co., Ltd.

|

Ndfeb Permanent Magnet

| Price: | 0.1~100.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

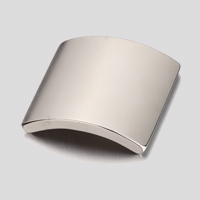

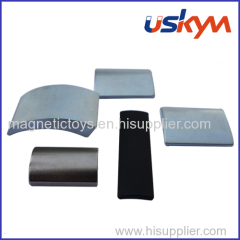

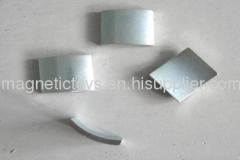

Sintered Rare Earth Neodymium magnets made from rare earth elements that are the most powerful permanent magnetic materials available.

Magnet NdFeB for Motor:

1. Materials: Rare earth magnet

2. Certification: ISO9001: 2000

3. Magnetic properties: High coercive force, (BH)max from 33 to 53MGOe, max working Temperature up to 230° C.

4. Grades: N35, N38, N40, N42, N45, N48, N50, 35M, 38M, 40M, 42M, 45M, 48M, 35H, 38H, 40H, 42H, 45H, 30SH, 33SH, 35SH. 38SH, 40SH, 42SH, 28UH, 30UH, 33UH, 35UH, 38UH, 28EH, 30EH, 33EH, 35EH etc

5. Shapes: Segment/ Arc or produce many shapes according to your request, Block, Sphere, Disc, Ring, Segment, Cylinder, Sheet and so on.

6. Sizes: R x r x H x Degree as per your request

7. Coatings: Metallic Zinc, Nickel, Nickel+Nickel, Copper+Nickel, Nickel+copper+Nickel, Gold, Organic Epoxy, Nickel+Epoxy coating and so on;

8. Applications: Widely used in motors, rotors, wind turbines/wind generators, etc.

9. Parameters: Grade(property), Size(R x r x H x Degree) or Drawing, Coating, Quantity, etc.

10. Note: Our NdFeB arc/segment magnet can produce as per your design, glad to give some suggestions if you need.

We provide a huge selection of Magnet NdFeB for motor commonly used in many wind generator plans with high coercivity, low temperature.

1. Materials: Rare earth magnet

2. Certification: ISO9001: 2000

3. Magnetic properties: High coercive force, (BH)max from 33 to 53MGOe, max working Temperature up to 230° C.

4. Grades: N35, N38, N40, N42, N45, N48, N50, 35M, 38M, 40M, 42M, 45M, 48M, 35H, 38H, 40H, 42H, 45H, 30SH, 33SH, 35SH. 38SH, 40SH, 42SH, 28UH, 30UH, 33UH, 35UH, 38UH, 28EH, 30EH, 33EH, 35EH etc

| Magnetic properties of sintered NdFeB magnet | |||||||||

| (Br) | (bHc) | (iHc) | (BH)max | ||||||

| GRADE | Tw °C | ||||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ||

| N35 | 1.18-1.23 | 11.8-12.3 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | ≤80 |

| N38 | 1.22-1.28 | 12.2-12.8 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | ≤80 |

| N40 | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | ≤80 |

| N42 | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | ≤80 |

| N45 | 1.32-1.37 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | ≤80 |

| N48 | 1.36-1.42 | 13.6-14.2 | ≥836 | ≥10.5 | ≥876 | ≥11 | 358-390 | 45-48 | ≤80 |

| N50 | 1.39-1.45 | 13.9-14.5 | ≥836 | ≥10.5 | ≥876 | ≥11 | 374-406 | 47-51 | ≤80 |

| N52 | 1.42-1.48 | 14.2-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 390-422 | 49-53 | ≤80 |

| N35M | 1.18-1.23 | 11.8-12.3 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | ≤100 |

| N38M | 1.22-1.28 | 12.2-12.8 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | ≤100 |

| N40M | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | ≤100 |

| N42M | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 318-342 | 40-43 | ≤100 |

| N45M | 1.34-1.39 | 13.4-13.9 | ≥876 | ≥11.0 | ≥1114 | ≥14 | 342-366 | 43-46 | ≤100 |

| N48M | 1.36-1.42 | 13.6-14.2 | ≥876 | ≥11.0 | ≥1114 | ≥14 | 366-390 | 46-49 | ≤100 |

| N35H | 1.18-1.23 | 11.8-12.3 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | ≤120 |

| N38H | 1.22-1.28 | 12.2-12.8 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | ≤120 |

| N40H | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | ≤120 |

| N42H | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 318-342 | 40-43 | ≤120 |

| N45H | 1.33-1.39 | 13.3-13.9 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 342-366 | 43-46 | ≤120 |

| N48H | 1.36-1.42 | 13.6-14.2 | ≥923 | ≥11.6 | ≥1274 | ≥16 | 366-390 | 46-49 | ≤120 |

| N33SH | 1.14-1.19 | 11.4-11.9 | ≥836 | ≥10.5 | ≥1592 | ≥20 | 247-270 | 31-34 | ≤150 |

| N35SH | 1.18-1.23 | 11.8-12.3 | ≥868 | ≥10.9 | ≥1592 | ≥20 | 263-287 | 33-36 | ≤150 |

| N38SH | 1.22-1.28 | 12.2-12.8 | ≥899 | ≥11.3 | ≥1592 | ≥20 | 287-310 | 36-39 | ≤150 |

| N40SH | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥1592 | ≥20 | 302-326 | 38-41 | ≤150 |

| N42SH | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥1592 | ≥20 | 318-342 | 40-43 | ≤150 |

| N45SH | 1.33-1.39 | 13.3-13.9 | ≥923 | ≥11.6 | ≥1592 | ≥20 | 342-366 | 43-46 | ≤150 |

| N28UH | 1.03-1.09 | 10.3-10.9 | ≥780 | ≥9.80 | ≥1990 | ≥25 | 207-231 | 26-29 | ≤180 |

| N30UH | 1.09-1.14 | 10.9-11.4 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 | ≤180 |

| N33UH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-263 | 31-33 | ≤180 |

| N35UH | 1.18-1.22 | 11.8-12.2 | ≥868 | ≥10.9 | ≥1990 | ≥25 | 263-287 | 33-36 | ≤180 |

| N38UH | 1.22-1.27 | 12.2-12.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 287-310 | 36-39 | ≤180 |

| N28EH | 1.03-1.09 | 10.3-10.9 | ≥780 | ≥9.80 | ≥2388 | ≥30 | 207-231 | 26-29 | ≤200 |

| N30EH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | ≤200 |

| N33EH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥2388 | ≥30 | 247-263 | 31-33 | ≤200 |

| N35EH | 1.18-1.22 | 11.8-12.2 | ≥868 | ≥10.9 | ≥2388 | ≥30 | 263-287 | 33-36 | ≤200 |

| N28AH | 1.03-1.09 | 10.3-10.9 | ≥780 | ≥9.80 | ≥2786 | ≥35 | 207-231 | 26-29 | ≤220 |

| N30AH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2786 | ≥35 | 223-247 | 28-31 | ≤220 |

| Note:The above mentioned data is given at room temperature. | |||||||||

| The above-mentioned maximum working temperature of magnet is changeable due to the ratio length and diameter,surface coating and environmental factors. | |||||||||

5. Shapes: Segment/ Arc or produce many shapes according to your request, Block, Sphere, Disc, Ring, Segment, Cylinder, Sheet and so on.

6. Sizes: R x r x H x Degree as per your request

7. Coatings: Metallic Zinc, Nickel, Nickel+Nickel, Copper+Nickel, Nickel+copper+Nickel, Gold, Organic Epoxy, Nickel+Epoxy coating and so on;

8. Applications: Widely used in motors, rotors, wind turbines/wind generators, etc.

9. Parameters: Grade(property), Size(R x r x H x Degree) or Drawing, Coating, Quantity, etc.

10. Note: Our NdFeB arc/segment magnet can produce as per your design, glad to give some suggestions if you need.

We provide a huge selection of Magnet NdFeB for motor commonly used in many wind generator plans with high coercivity, low temperature.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Sintered Ndfeb Permanent Magnet

Permanent Ndfeb

Permanent Magnet

NdFeB Magnet

Permanent Ndfeb Magnets

Ring Permanent Magnet

More>>